Advantages of BMS-60 motor pulling machine:

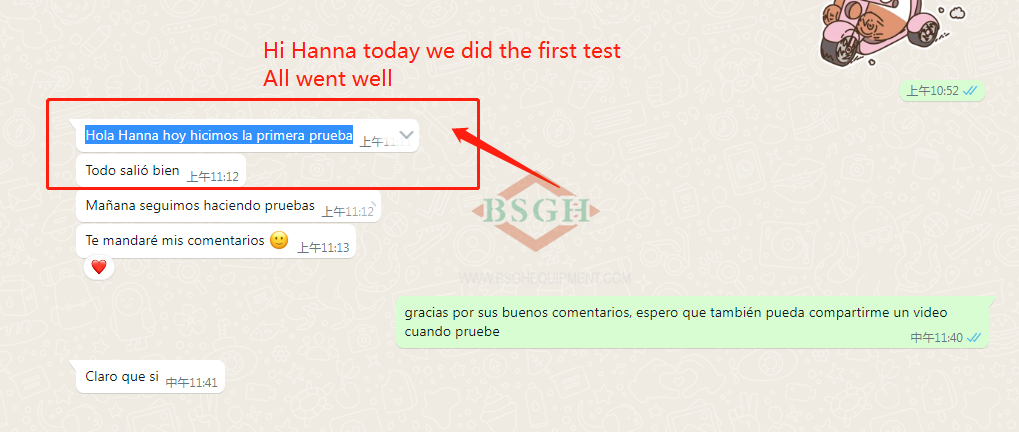

High-efficiency Electric Motor Stripping Machine is testing for our client.

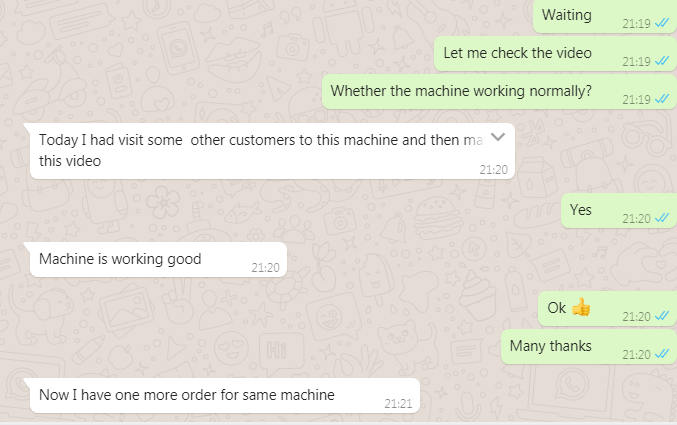

Our customer want a high-automation machine, it’s too trouble adjust baffle frequently, so we recommend BSM-60 to him. The baffle of BSM-60 will automatically clamp the stators according to the diameter of the motor stator, and then pull out the copper winding, which make it convenient for customer to recycle the copper. Our customer recycle scrap motors by himself, he said this machine saved his time and labor a lot.

BSM-60 electric motor stripping machine is equipped with a hydraulic stator copper cutting system and a hydraulic stator copper pulling system. The machine can handle waste motor diameters ranging from 40mm to 120mm automaticly, including motors from air conditioners, water pumps, industrial motors, etc.

This model is more convenient compared to other electric motor recycling machines, this model is the only one on the market that does not require adjusting the baffle according to the stator diameter, most of our motor recycling machines are unique on the market.

| Model | BSM-60 Motor Wrecker |

|---|---|

| Process Range | 40-120MM |

| Power | 4KW |

| Machine Size | L1370*W1040*H1460MM |

| Machine Weight | 508KG |

| Voltage | 380V50HZ or customized |

There are three important components: the hydraulic motor stator copper cutting system and the hydraulic stator copper pulling system and the hydraulic baffle system.

Cutting System:

Equipped with a robust hydraulic structure and reinforced blades for superior performance and extended lifespan.

Pulling System:

This Electric Motor Stripping Machine also adopt 8 claws to pull out the entire copper winding of the motor stator.

Baffle:

The baffle can automatically and firmly grasp the stator based on its diameter. No need to change the baffle when processing stator diameters ranging from 40mm to 120mm.

First, cut off one end of the motor stator copper winding through cutter.

Second, put the copper stator into the baffle, and the baffle will automatically clamp the motor stator.

Finally, the claw grabs one end of the copper winding and pulls out the entire copper winding.

I’m seriously impressed. This machine is worth every penny.

I really enjoy using the machine and have already purchased two. Highly satisfied!

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :