Professional Scrap Compressor Recycling Machine Manufacturer

- compressor case recycling machine

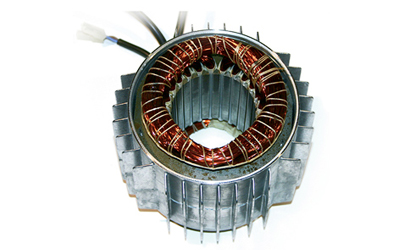

- compressor stator recycling machine

Scrap Compressor Recycling Machine Video Project

3T not only has compressor recycling machine but also has other electric motor recycling machines, providing you one-stop shop for all kinds of motor recycling machines.

Playlist

0:36

0:45

Compressor stator cutting and pulling machine is in processing longer compressor stator in the video. You can see BSC is very easy to pull copper winding out.

This video is testing for our Germany customer, you can see it’s safe and high efficiency in processing. The compressor casing is dismantled by 4 high speed rotating blades.

Professional Compressor Recycling Machine Factory

If your compressor is very slender, such as a submersible pump compressor, we can also customized for you.

What Is Scrap Compressor?

Most of the waste compressors come from refrigerators, ice machines, air conditioners, water pumps, etc, It has a wide range of applications. A compressor contains a large amount of copper, which is valuable for recycling. The main component of the compressor is similar to normal motor.

Compressor case is strong and have oval and round shape, metal made, if you want to recycle copper winding you need to take out the compressor case first and then recycling inner stator.

how to recycling compressor?

(To recycle scrap compressor, normally need 3 steps with different machine.)

Remove the motor case

- Put the scrap compressor on the compressor casing cutter machine, four rotating blades will quickly cut the waste compressor case.

Cut One End Of Copper Winding

- Put the compressor stator under cutter, and cut off one end of the copper winding.

Pull The Copper Winding Out

- Finally compressor stator pulling machine pulls out copper winding and you can get the pure copper.

3T is a professional provider of copper recycling solutions and has been engaged in recycling machinery sales for more than 25 years.

Our products have a market share of about 90% in China, we are also exported to Europe, South America, North America and all over the world.

Have passed CE certification and we have accumulated many high-quality customers from all over the world.

Purchase suggestions when buy a compressor recycling machine?

Choose the most suitable scrap compressor machine. Generally speaking, there are 3 steps to recycling a compressor: 1. cutting the shell 2. cutting the stator 3. pulling the copper winding. We have designed different models for each step. Make sure that you choose the function you want.

Ensure that the inner diameter of the stator is appropriate. A scrap compressor machine with a suitable function not only boosts recycling efficiency but also extends the service life of the machine.

Look for a machine made from high-quality materials and known for its durability. Investing in a reliable machine will save you maintenance costs and ensure a longer lifespan.

Good Reputation of 3T Compressor Recycling Machine

Do you also want to recycle copper winding wire from compressor scrapping electric motors? You can know more about our scrap compressor machine from here.

There are a few manufacturers who specialize in selling compressor recovery machines, for 3T scrap compressor machine although less but professiona.

——- Fabian / From France

The machine is easy to control and can improve recycling efficiency. I think it is necessary if you want to do a motor recycling business.

——- Ethan / From Porgutal

3T really has a complete range of motor recycling machines. I have been troubled by how to remove the compressor case for a long time, but now 3T has solved my problem.

——- Michael / From Russia

FAQs

No, it is specifically designed for recycling copper from used compressor. you can find the most suitable motor recycling machine in 3T.

Of course, our company’s compressor recycling machine series products include recycling all-in-one machine and independent compressor shell cutting machine. You can buy according to your needs.

We are a trusted and authentic company, there is no reason to lie to you. And we have been doing international business for more than 25 years, and our alibaba store for over 11 years, we will not damage our company’s reputation, you can totally trust us.

Don’t worry, we have sold many machines, you can refer to the feedback from our customers, they have processed different types of compressors, and all the feedbacks to us are positive.

Or, if you still don’t believe me, you can send us your used compressor and we’ll test the machine with your compressor and you just have to check the test results.

All of our machine is whole of machine and very easy to installation, only need to connect the three phase,then can work directly, also we have manual book for you once you receive the machine, no need worry!

You can find a agent to help you do the import procedure, it is very easy but you need to pay some cost to them, lots of agent company in the market, you can find it very easily. Machine need 10-15 days production time, during this time, you have enough time to find a forwarder.

You can send us your raw material picture, then we will according your material recommend the suitable machine for you, my friends.