Best Electric Motor Machine For Sale

If you are looking for highly efficient motor recycling equipment, you will find the perfect solution at 3T. We provide a variety of electric motor recycling machines that can help you recycle various motor stators, car starters, compressors, new energy motors, car magnetic switches, etc.

Your trustworthy electric motor

machine manufacturer

3T is a high-end electric motor recycling machine brand in China that focuses on researching and manufacturing various electric motor recycling equipment. Among the electric motor recycling machine brands in the world, our professional equipment has the most complete models and the most powerful functions, designed to help all of our partners improve productivity and simplify operational processes. Over the years, our R&D team has continuously improved and updated the machines based on customer needs and feedback, making them tested in the global market. In the future, we have the ability and confidence to become the world’s number one electric motor machine brand and create more top-quality electric motor recycling machines.

Quality Assurance

We care more about machine quality than sales. 3T has its own manufacturing plant in Taizhou, Zhejiang, China. All raw materials are carefully selected premium steel. We strictly control the machine's quality during the production process. Each production step meets the highest quality standards, eliminating the possibility of inferior machine quality from the source.

Ultimate cost performance

We strive to find the perfect balance between the quality and price of the machine. While ensuring that the motor recycling machine is top quality, we will try to quote you the lowest price. We are willing to establish a long-term partnership with you with the greatest sincerity. Our motor recycling machine can always maintain the best performance during long-term operation, and the value it can bring to you far exceeds its price.

Personalized customization service

We offer a variety of flexible customization options. If you want to customize the color, voltage, accessories, your company logo, or even the material of the blades, you can discuss it with our staff and our product design team will create the best solution for you.

Formal transaction

All of our export transactions strictly comply with international trade regulations, and we maintain positive and clear communication with customers on every transaction detail to ensure reliability, so that each of our customers can get a fully compliant experience. Moreover, we will keep customer information confidential and will not disclose customer privacy to anyone.

Best electric motor recycling solutions

from 3T

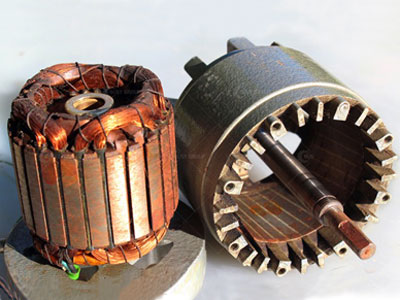

common electric Motor

recycling machine

The elctric motor recycling machine is mainly used to recycle the copper windings in motor stators. According to different functions, they are mainly divided into three types: motor stator cutting machine, motor stator pulling machine, motor stator cutting and pulling machine and motor case breaking machine. Different models of machines have different processing diameter ranges and different function.

Vedio Display

The Motor Stator Cutting Machine

- It can remove the motor shell and cut the motor stator in half.

The Motor Stator Pulling Machine

It has a single pulling function, it can pull out the copper winding from the motor stator without a shell and with one end of the copper windings cut.

Motor Stator Cutting and Pulling Machine

It is the most cost-effective type, and is more cost-effective than buying a single cutting machine and a single pulling machine separately. It has a cutting part and a pulling part, which can cut one end of the copper winding and then recycle the entire copper winding.

Car starter rotor

recycling machine

Recycling a car starter mainly requires four steps: cutting, pressing, heating, and pulling. Combining our four machines can effectively recycle car starter rotors.

Work Procedure

Click to play the video on the right and refer to the description below to understand how the car starter rotor is recycled.

You need to use the auto starter rotor cutting machine to cut the motor, making the pulling step easier.

The hydraulic scrap metal wrecker machine will help you press the rotor for further recycling.

Use the car starter heating machine to heat the rotor. This step can effectively prevent the copper winding from sticking to the motor.

Use the auto starter motor pulling machine to pull out the copper winding.

Car alternator

recycling machine

This type of machine is specially designed for recycling car alternators. It combines cutting and pulling functions in one machine. If you only need cutting or pulling functions, you can also just buy a single cutting machine or a single pulling machine.

Suitable for various scrap car recycling centers, scrap metal recycling stations, and scrap yards.

Car Alternator Cutting Machine

- Power: 3KW

- Weight: 200KG

- Size: L1130*W800*H900MM

Car Alternator Pulling Machine

- Power: 4KW

- Weight: 220KG

- Size: L1100*W770*H1000MM

Car Alternator Cutting And Pulling Machine

- Power: 5.5KW

- Weight: 334KG

- Size: L1170*W980*H1090MM

Automotive magnetic switch recycling machine

Waste magnetic switches contain a high copper content and worth recycling. Using our automotive magnetic switch recycling machine can efficiently recycle magnetic switches and help you make money quickly.

- Power: 3KW

- Pulling Part Weight: 110KG

- Pulling Part Size: 650*510*920MM

- Gas Station Weight: 55KW

- Gas Station Size: 560*460*800MM

- You only need to place the magnetic switch on the machine and fix it, and the machine will automatically complete the removal process.

- After machine processing, you only need to manually remove the copper winding on the magnetic switch.

- Efficient processing, it only takes 10 seconds to remove a magnetic switch.

Transformer motor stator recycling machine

The transformer motor stator recycling machine is specially designed for recycling copper windings in small transformers.

- It is suitable for small transformers with an outer diameter less than 100 mm.

- The machine consists of a cutter and a pulling part. The cutter is mainly used to cut the transformer in half. The Pulling part can pull out the entire copper winding.

- It adopts a small sharp knife and a special four-claw design, which is very suitable for recycling various transformers.

Compressor cutting machine

Compressor cutting machine can remove the outer shell of compressors from refrigerators or air conditioner. We mainly have 2 types of compressor cutting machines for you to choose from. Also, you can further recycle the copper windings with the BSC Electric Motor Dismantling Machine.

New energy vehicle motor stator recycling machine

New energy vehicle motors are different from ordinary motors in structure and copper winding method, so it is difficult to recycle them with ordinary motor recycling machines. 3T is the first brand in the industry to develop equipment to recycle new energy motors.

- Power: 5.5KW

- Voltage: 380V/50Hz

- Weight: about 560KG

- Size: L1330*W1080*H1250

- Motor Speed: 1400r/m

- It adopts a structure more suitable for new energy motors and greater power, and can easily recycle the copper windings in new energy motors.

- There are mainly 12-claw and 16-claw grippers, these special grippers are specially designed for recycling special EV motor stators.

New energy motor rotor recycling machine

The new energy vehicle motor rotor contains highly valuable strong magnets, which can bring you ideal profits. To recycle these strong magnets you mainly need two machines.

rotor shaft pulling machine

The motor shaft pulling machine adopts advanced hydraulic technology, which can always maintain stable performance.

- Fix motor rotor on the motor shaft pulling machine, and then machine will automatically push out the rotor shaft.

car motor rotor heating machine

The car motor rotor heating machine has a smoke exhaust function, which can remove harmful gases in time and protect the health of operators.

Use the car motor rotor heating machine to heat the new energy motor rotor. When this step is completed, you can manually recover the strong magnets in the motor rotor.

Electric motor shredder line

The electric motor shredder line is a large motor shredding and separation production line, suitable for recyclers with a very large number of scrap motors.

- Power: 155KW

- Voltage: 380V Or Customized

- Processing Range: 50-250MM

- Capacity: 1800-2200KG/H

- Machine Size: 15000*58000*4500MM

- The main parts include pre-shredder, main crusher, air separator, magnetic separator, vibrating screen dust collector, etc. It is a very well-equipped production line.

- It can processvarious motors with diameters ranging from 50 to 250 mm, and the processing capacity is 1800 to 2200 kg/h.

- Before entering the machine, you need to remove the motor housing.

Why we need electric motor machine?

- vaule

Waste motors are a raw material with high recycling value. Its high copper content and low purchase price make it an ideal raw material that can quickly bring profits to recyclers.

- improve efficiency

By using electric motor machine, recyclers can improve recycling efficiency, realize automated production, greatly reduce labor costs and save time.

- profit

The copper winding recycled by the electric motor machine is complete and free of impurities. This high-quality copper winding is usually more profitable than copper granules.

Advantages of 3T electric motor machine

excellent performance

Our electric motor machine has excellent performance, it will not cause any copper loss, can maximize the extraction of all copper, the recovery rate is almost 100%, and can help you maximize profits.

Easy Operation

The machines are equipped with foot switches, which not only make the operator’s operation more comfortable but also ensure the operator’s safety.

Powerful Design

High torque design, can easily handle all kinds of electric motors.

Strong Jaws

We use the strongest machine structure and high-hardness raw materials to manufacture the machine, especially the machine’s jaws. We test the jaws many times to ensure that they are strong enough and not easily damaged.

Complete Service

Our machines are of top quality and are more durable than 97% of similar machines on the market. They usually won’t break down if they are in normal operation for a long time. Even if the machine breaks down, we will provide a one-year warranty to protect your rights and interests. During the warranty period, we will support free repair or replacement of non-artificially damaged parts of your machine.

Saving Labor Cost

The user-friendly machine allows operators to use the machine proficiently without training, and only one operator is required during the operation, saving you a lot of labor costs.

Our factory and production workshops

Our company has its own factory in Taizhou, Zhejiang, China. Our design team can flexibly customize machines for you according to your special needs. Our manufacturing team pays attention to every detail in the production process and strictly controls the machine quality according to the highest quality standards. Our production line uses advanced equipment and technology to improve production efficiency while ensuring top machine quality, ensuring that you can receive the machine as soon as possible.

How To Get Used Electric Motor Pulley Removal Machines From Us

If you need equipment that can efficiently recycle used motors, do not hesitate to send us your inquiry. Our staff will give the most professional advice and help you complete the entire ordering process.

01.

Inquiry And Consultation

Please send us your motor type and quantity, we will recommend you the most suitable machine according to your existing raw materials and business plan.

02.

Customization And Quotation

If you want to customize the machine, please tell us your requirements and we will design a solution that exceeds your expectations.

03.

Order Confirmation And Manufacturing

After confirming the machine model and customization plan, you can pay the advance payment first. After receiving the advance payment, we will immediately prepare for the production.

04.

Delivery And After-Sales Support

After production, we will arrange the shipment on the agreed date and closely monitor the shipping situation until you receive it. If you have any questions during use, our staff will quickly answer them online.

FAQs

I just need a device to cut old motors, can I buy it separately?

Yes, 3T has designed single-cut models for almost all types of motor recycling machines. Their blades are not only highly hard but also very durable.

Can the car alternator recycling machine recycle other types of motors?

No, the car alternator recycling machine is specially designed for car alternators. If you have other kinds of motors, please send their pictures to our staff for better recommendation.

What kind of payment methods can you accept?

We accept T/T payment. You can pay 30% of the machine price in advance. We will send you a test video before shipping, and then you pay the remaining 70%.

How should I choose among so many models?

You can tell us your motor types and diameters, or immediately send us your motor pictures, and we will help you choose the most suitable model.

Lets Tell Us About Your scrap motor machine Needs

Let us know your specific needs for motor recycling machines. We’ll devise personalized processing strategies aimed at optimizing your recycling workflow and the quality of final product.

- Whatsapp/Viber: 008613772508206

- Email: coppergranulator@bsghrecycling.com

- Website: https://3t-motorrecycle.com/