Electric motor pulley removal machine is a professional automatic equipment used to dismantle motor pulleys from all kinds of scrap motors. It is equipped with a hydraulic system and has the characteristics of high efficiency, high durability, and stable performance. Our electric motor pulley removal machine supports the complete removal of motor pulleys, rotor bearings, and gears without causing any damage to these components. You can put them back into the motor for reuse.

The electric motor pulley removal machine can handle motors of various sizes and can be widely used in factories, oil fields, docks, construction, railways, machinery, and other fields. With our electric motor pulley removal machine, you don’t need to use wrench and other tools to manually dismantle the pulley, saving both time and effort.

3T is very expert in manufacturing various motor recycling machines including electric motor pulley removal machines. We have the most powerful and complete motor recycling machines in the world, they can meet all your motor recycling needs. In addition to machines capable of handling motors, we also offer a wide range of high-quality copper wire stripping machines, cable granulator machines, radiator recycling machines, etc.

BSGH Granulator has been in the copper recycling industry for more than 25 years. With the continuous accumulation over the years, we have cultivated a team with rich experience and professional industry knowledge. Our team is not only committed to developing higher quality and more durable machines, but also provides comprehensive one-stop services and professional advice for your recycling business.

Our machines have been hot-selling in 80+ countries and regions and have been tested by the global market. Our machines have attracted a great number of customers with stable performance, high efficiency, and long service life. They come from all over the world and have different requirements for the machines. After comparing BSGH with other brands of products many times, they finally chose to buy BSGH machines. And most of the customers sent us good comments as soon as they received the machines, and nearly half of them have reached multiple cooperation with BSGH Granulator.

BSGH Granulator has always put integrity first in seeking long-term development. All the information about the machine you see on our official website is true and valid, all the machine parameters are real, all the processing capacity of the machine can be truly achieved, and all the pictures are taken from the real object. You can feel confident in your decision to cooperate with us.

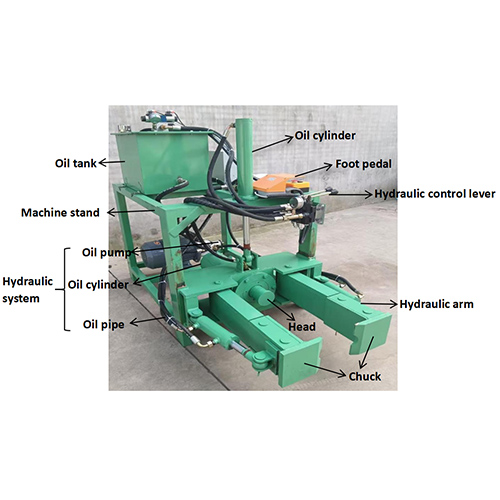

The motor pulley removal machine is consist of the following parts: oil tank, machine frame, hydraulic system, oil cylinder, foot pedal, hydraulic control level, machine head, machine chunk, hydraulic arm

Technical Parameters | ||

Parameters Model | 60 Motor Pulley Puller | 100 Motor Pulley Puller |

Size | L1760*W850*H1500 MM | L1850*W880*H1540 MM |

Volume | 2.2m3 | 2.5m3 |

Weight | 460kg | 520kg |

Voltage | 380V / 50Hz | |

Power | 5.5KW | |

Motor Speed | 1400r/min | |

Rated Pressure | 20MPA | |

Chuck Entrance Size(Max) | 90cm | |

Using the electric motor pulley removal machine is not complicated, you can refer to the following steps

First, place your motor between the two clamping arms used for fixing, use the hydraulic control lever to adjust the lifting and position of the clamping arms, and after adjusting them properly, use the foot switch to control the clamping arms so that they clamp the motor.

Second, you need to put one end of the iron rod against the center of the motor bearing and the other end against the hydraulic puller of the machine.

Start the machine, and the hydraulic puller will slowly push forward. As the hydraulic pressure increases, the pulley will gradually be pulled out of the axis.

Finally, after the machine stops, you can remove the pulley manually.

Connect the three live wires to the electric box of the machine, after connect to the power, machine motor maybe forward or reverse rotation. Forward rotation can be used directly, and reverse rotation requires changing the wiring head (just change the middle of the three live wires with any of the side wires) is ok.

If your electric motor pulley removal machine is a custom-made single-phase model, you only need to connect one live wire and one zero wire.

The machine generally needs to add 20~25KG hydraulic oil (the oil volume should account for more than four-fifths of the tank), usually we add national standard 46# hydraulic oil. There is a refueling port on the top of the black tank of the machine. When refueling, you only need to inject hydraulic oil from the refueling port. This refueling method can ensure the machine to run more stably for a longer time.

There is a black, rotatable screw cap near the machine handle. Unscrew the screw cap, you can see the hexagonal screw used to adjust the pressure.

The actual maximum pressure of the machine has been adjusted at the factory. If you need to adjust it, please make fine adjustments. It is not recommended to adjust the range more than a quarter of a turn each time, and it can be adjusted in multiple times or you can consult our staff.

The specific method of adjusting the pressure is to rotate the black hexagon socket screw clockwise to increase the pressure, and counterclockwise to reduce the pressure. Please also note: It is not recommended to continue working with more than 10 pressures for a long time (except for professionally customized high-pressure systems).

The main switch is on the right side of the machine. The green button and the red button control the power on and off respectively. Press the green button to start the power and the red button to turn off the power, and the machine will stop running immediately.

The machine has two hydraulic control levers, one for moving the main cylinder forward and backward, and the other for moving the clamp arm up and down. In addition, you can also use the foot switch to control the clamp arms to clamp and release.

3T has its own factory in Taizhou, Zhejiang, China. Our design team designs electric motor pulley removal machines that meet the global market needs from the customers’ perspective, and we can flexibly customize machines for you according to your special needs. In addition to electric motor pulley removal machine, we also have a variety of motor recycling machines with a very complete range. Our manufacturing team pays attention to every detail in the production process and strictly controls the machine quality according to the highest quality standards. Our professional quality inspection team will conduct multiple tests on each machine to ensure that every machine we send out is of the highest quality. In addition, our production line uses advanced equipment and technology to improve production efficiency while ensuring top machine quality, ensuring that you can receive the machine as soon as possible.

After receiving the advance payment, we will let the factory produce the machine immediately. When the machine is completed, we will conduct a rigorous test on the machine and send you a video of the test process. If you are sure there is no problem, you can pay us the balance of the machine, and then we will send the machine to the port closest to you.

Simply contact our sales team to discuss the sizes and quantity of your motors, machine price, and delivery choices, we will try our best to help you buy a satisfactory machine.

Please send the size, quantity and photos of your motor to our staff and we will recommend the right model for you.

If you have any special requirements, please let our staff know. We have a wealth of customized options to meet your different requirements, and we will quote you the lowest price.

After receiving the deposit, we will immediately send your requirements to the factory to start the production of the machine. Please pay close attention to the update of order status and shipping.

We support free shipping of the machine to the base port of your country, and we will also provide after-sales service such as setup help, maintenance guidance, 24/7 customer care.

Let us know your specific needs for motor recycling machines. We’ll devise personalized processing strategies aimed at optimizing your recycling workflow and the quality of final product.

© All rights reserved by BSGH/3T.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :