WE ARE PROFESSIONAL

Leading Electric Motor Wrecker Machine Factory

All Solutions and Multi-Type fit for your various demands, save time and get more profits.

Motor Wrecker Machine Video Project

Playlist

2:24

1:25

0:54

0:18

0:25

1:15

0:19

0:42

0:27

0:19

With a range of discarded motors, the machine efficiently dismantles and sorts valuable components, you can see from the video its multifunction and versatility.

A customer from the United States recently purchased our motor recycling equipment. They provided us with a feedback video show the machine operating excellently at their recycling facility. They mentioned that the machine is easy to operate and can process a significant number of motors in a day. Furthermore, they expressed satisfaction with the machine’s ability to ensure no residual copper is left behind, worthwhile purchase.

BSM-50 scrap motor dismantling machine is cutting and removing the motor case easily.Our motor cutting machine incorporates advanced technology and premium materials, ensuring durability and high-efficiency operation during cutting processes.

This machine is for our USA customer. Motor cutting machine is equipped with flat blade and sharp blade, can better cut motor shell and motor stator.

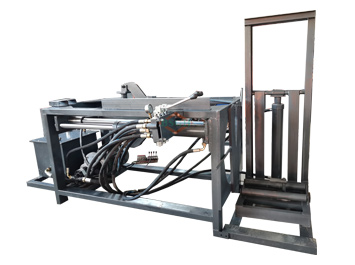

ST-400 is for our Poland customer, consists of a 6-jaws claw on the left side for pulling the copper windings from motors; a cutting device on the right side equipped with both flat and sharp blades for cutting motor casings and stators. In the video, the workers demonstrated the scrap motor recycling process, showing how simple and efficient it is.

What are you waiting for? Take action now and join us!

Through the video, we can see that our BSM-30 motor wrecker can process a wide range of scrap motors, which is useful and powerful.This gripping clamp is highly controllable, with three adjustable handles located beside it for precise positioning and gripping control. Despite its large size, it is remarkably agile.

MR-W is for our German customer long time ago, he have much washing machine motors, With the help of this electric motor recycling machine, we transformed our old stockpile of motors into valuable resources, giving our business a fresh start.”

Our customer, a prominent industry player, successfully tests our state-of-the-art motor recycling machine.

In a remarkable display of technological innovation, a recent video captured the moments when a satisfied customer tested their newly acquired motor recycling machine, supplied by our company. This exciting footage not only highlights the superior quality and functionality of our cutting-edge machinery but also reinforces our commitment to environmental sustainability and waste reduction. Let’s delve into the details of this extraordinary story, including the customer’s enthusiastic reaction and their highly positive feedback.

This motor recycling machine is definitely worth considering. As you can see, it features an entrance in front of the gripping claw, which can automatically adjust the baffle according to the size of the placed motor. This high level of automation makes it convenient and efficient.

Used Electric Motor Wrecker For Sale

Almost all motor wrecker machine provided by 3T adopts advanced technology and hydraulic structure, which is high efficiency and saves time and effort in operation. Furthermore, our design ensures convenient operation and maintenance, offering you a user-friendly recycling solution.

ST-400 Motor Stator Cutting Pulling Machine

- Stator Diameter: 90-250MM

- Size: 1800*900*1950MM

- Power: 5.5KW

- Bigger diameter pending prove.

MR-W Motor Copper Winding Puller

- Stator Diameter: 40-75MM

- Size: 1060*570*890MM

- Power: 2.2KW

- Especially for washing machine motor.

The composition of Common electric motors

As an integral part of our life, scrap motors are mainly found in various electrical appliances and machinery.

There’s many kinds of motor, now we mainly understand normal electric motors and it’s structure first.

For normal electric motor is mainly composed of:

- Motor Casing: Aluminum or Iron

- Motor Stator: Copper Winding or Aluminum Winding

- Motor Rotor

In general, the motor diameters of different electrical appliances are different. For this reason, we have developed series motor wrecker recycling machine that can handle ordinary motors of different sizes.

For different-size motors, 3T provides a suitable model to process.

Raw materials for Electric motor wrecker recycling machine

3T Solutions Provider for Electric Motor Wrecker

Steps To Recycle A Scrap Motor

Generally speaking, it needs 3 steps to recycling a scrap motor.

First step is to remove the motor outer case; no matter you manual process or machine process.

Second step is to cutting copper winding wire from one end of copper winding or cutting from middle.

Third step is to pull copper winding out from silicon steel, then you can get it separated.

Above steps, 3T always have the suitable motor wrecker machine for you, check in right side!

What We Provide

3T provides solutions for All Your different kinds of scrap motor recycling to meet wide needs.

Motor cutting machine is specially responsible for cutting motor casing or motor stator.

Motor stator pulling machine, which is specially responsible for pulling the copper winding out of the motor stator.

Multi-functional motor recovery machine, which integrates the cutting part and traction part.

Multi-functional motor recovery machine, which integrates the cutting part and traction part.

Electric Motor Wrecker Machine Structure

All machine use a hydraulic station as power, it’s the main part of machines provide reliable performance throughout the recycling process.

Cutting Part

The cutting part of electric motor wrecker can be divided into three types depending on the different blades used. And each is designed to cater to different types of motors.

This type of cutting is used to halve the motor case. ST-400 and BSM-50 are equipped with flat blades.

Specifically designed for cutting the motor stator. Machines such as ST-400 and BSM-50 use both flat blades and sharp blades for the cutting process.

It is employed to cut the copper winding at one end of the motor stator, enabling easier extraction during the pulling process.

MR-W, BSM10/20/40/60, BSC mainly rely on curved blade for cutting purpose.

(How to use semi-rod blades? pls check below application.)

How was each type looks like? pls check it.

How to Use Cutter Head:

Selecting the appropriate cutter bushing is crucial, or else will break blades or damage stators, thereby affecting the overall performance. Bushing selection primarily depends on the size of the stator’s inner diameter, better to choose a bushing smaller than the stator’s inner diameter but close to the inner diameter of the stator is best.

Cutter Limit Adjust Method:

Loosen the screws of the cutter and make slight adjustments until it reaches the suitable position. After that, tighten the screws.

Pulling Part

Twelve Jaws Clamp: Similar to the eight-claw clamp, the twelve-claw clamp is another type of specialized jaw used in special motors and companies.

In this part, apart from the gripping jaws, the most important component is the stopper plate. The stopper plate is used to prevent the entry of the iron core of the stator and ensure the smooth gripping of the copper wire. An appropriate stopper plate should block the stator iron core without obstructing the copper wire.

- Step on the copper gripper foot switch. When the gripper retracts to the cylinder, press the emergency stop button to stop the operation.

- Loosen the two (or four) screws on the stopper plate.

- Replace the stopper plate with a suitable one.

- Finally, tighten the screws on the stopper plate.

The single wire pulling process is achieved by utilizing three control levers to control three hydraulic cylinders respectively.

- One lever controls the movement of the hydraulic clamp: Lifting the lever hydraulic clamp back, while pushing it down, hydraulic clamp will move forward.

- Another lever controlthe lifter: Lifting the lever, lifter will move higher, while pressing it down, lifter will move lower.

- The third lever controls the gripping action of the hydraulic clamp: Lifting the lever allows the clamp to grip the copper wire, whereas pressing it down opens the hydraulic clamp, facilitating the removal of the pulled copper wire.

Advantages of BSGH Motor Wrecker Recycling Machine

Complete Solutions

You can get solutions for any of your scrap electric motors.

Improve copper recycling efficiency and save costs

The emergence of motor recycling machine is to improve work efficiency and reduce copper loss. The motor wrecker released by 3T is multifunction and high efficiency, and only one person can operate the machine well, which can help you save costs.

No copper loss

3T Electric motor wrecking machine adopts advanced technology, which can completely disassemble the motor without destroying the copper winding. And there will be no copper loss in the whole recycling process, which will bring you more profits.

Quality assurance

More than 25 years experience makes BSGH/3T constantly improves and innovates, performance of BSGH motor recycling machines is perfect and haven't negative reviews after received. Meanwhile, due to factory directly sales, If you plan to buy a cost-effective motor recycling machine, BSGH must be your best choice.

What Did People Say about 3T Motor wrecker Recycling Machine?

Choose 3T For a Prosperous Future

Ordinary scrap electirc motor wreckers have big development prospects in future. As a main component of electrical appliances, waste electric motors contain valuable copper resources, recycling and reusing of these copper is an inevitable trends as resource concerns grow. And with the rapid development of electrical automation, the output of waste motors continues to increase, because less people can realize recycling scrap motor profit, so motor recycling profit increases accordingly.

With a Full Range of Solutions:

We provide a comprehensive selection of electric motor wrecker machine solutions to meet the diverse needs of our customers. We have all kinds of motor recycling machines. Whether you require streamlined processes or cheap single Electric motor wrecking machine, or enhanced efficiency, our solutions are cater to your specific requirements.