Our BSM-10 Electric Motor Scrapping Machine is running well in customer’s factory!

Our customer bought 3 sets of our electric motor scrapping machine last year. He bought a copper stripping machine 3 years ago, satisfied with the performance of the machine, so he bought our machine again with his recycling business expanding.

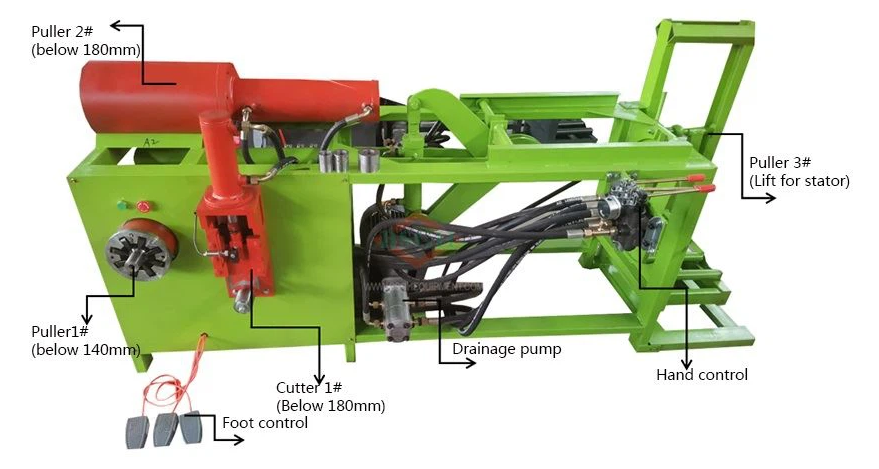

BSM-10 is a highly efficient and multifunctional scrap electric motor wrecker machine designed to accommodate various diameters of scrap motor stators. It can help you easily cut the scrap motor stators and extract the copper windings in one machine. BSM-40 is on the basis of this model, updated one, now we recommend customer to choose BSM-40, better performance and speed.

| Model | BSM-10 Electric Motor Wrecker | BSM-40 Electric Motor Recyclers |

|---|---|---|

| Power | 5.5KW | 7.5KW |

| Machine Weight | 750KG | 670KG |

| Range | Stator Diameter 50-500MM | Stator Diameter 50-500MM |

| Machine Size | 2400*1100*1300MM | 1940*1430*1150MM |

BSM-10 electric scrapping machine is similar to BSM-40 electric motor recyclers, they all have 1 cutting blade and 3 pulling parts, processing range are also same. The difference is the structure and the operation of whole machine. You can check BSM-40 electric motor recyclers page.

BSM-10 scrap motor cutting and pulling machine can process scrap motor stators with a diameter range of 50 to 500mm.

This machine consists of one cutter machine, three puller machines, and a lifter. The pictures below will provide you with the details of the machine.

How do these parts work during recycling? Please check out the video.

Make sure the electrical box is dry and clean.

Please ensure that there are no flammable materials around the machine.

Remember to regularly apply lubricant to the cutter and the running racks of the claws.

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :