BSM-30 is test running for our USA customer.

The customer wants to buy a motor recycling machine, but there are many manufacturers, he doesn’t know how to choose the best one, we advise them to visit our factory to have a clear understanding of our brand and quality, this video was taken when the customers visited our factory. After visiting, the customer ordered our machine on the spot without hesitation.

BSM-30 electric motor winding puller is a machine that extracts copper windings from scrap electric motors within 500MM diameter, these machines are often used together with a motor stator cutter machine BSM-20 or BSM-40 or single cutting machine to recycle copper.

This equipment is widely used in various recycling stations, motor factories and motor repair shops to recycle scrap motors.

(Here are several models for similar structure machines for you to choose.)

| Model | BSM-30 Motor Recycling Machine | BSM-40 electric motor recyclers | BSM-10 Electric Motor Scrapping Machine |

|---|---|---|---|

| Motor Power | 5.5KW | 7.5KW | 5.5KW |

| Machine Size | 2310*770*950MM | 1940*1430*1150MM | 240*1100*1300MM |

| Machine Weight | 395KG | 670KG | 750/690KG |

| Parts | 1 Pulling Part | 1 Cutting Part, 3 Pulling Part | 1 Cutting Part, 3 Pulling Part |

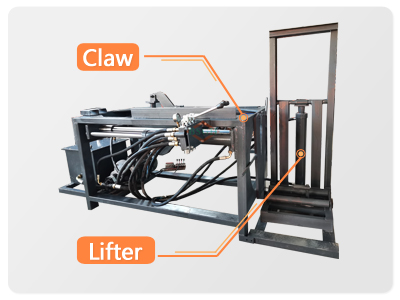

BSM-30 electric motor winding puller structure is simple, contains a powerful hydraulic plier and a lifter.

The lifter is used to save energy during the processing of large scrap motor stators.

Before pulling, use a motor cutting machine to cut one end of the copper winding of the stator first.

Step 1

Fix the scrap motor in the lifter and control the claw to approach it closely.

Step 2

Pull the copper out and rotate the motor to ensure that all the copper windings are pulled out.

Our professional staff will provide you with the most comprehensive service from pre-purchase to after-sale. We offer 24-hour online consultation and will provide you with optimal recycling solution to meet your needs.

3T provides the most complete range of machines for recycling various types of waste motors. If your materials are unique or you have special requirements, we can customize the machine for you.

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :