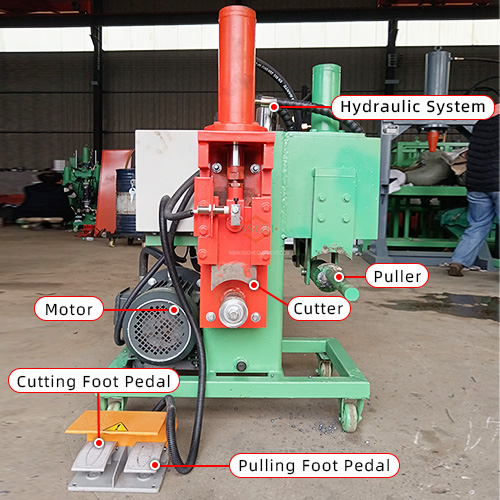

Our newest Mini BST electric motor cracker is specifically designed for recycling copper windings from automotive motor stators. The compact design and affordable price make it an ideal solution for small to medium-sized customers to maximize value and efficiency.

Watch this quick demo to see how our small electric motor cracker effortlessly extracts pure copper windings from scrap car alternators. Here’s how it works:

Designed for users who need professional performance in a smaller footprint, with a limited budget, Mini BST retains all the core capabilities while offering greater flexibility and accessibility. As this electric motor cracker is the advanced, space-saving version of our classic car alternator stator copper pulling machine. Below is a comparison of key parameters between them:

Model | Mini BST | Car Alternator Cutting and Pulling Machine |

Weight | 220kg | 334KG |

Size | L800*W950*H1000MM | L1170*W980*H1090MM |

Power | 3KW | 5.5KW |

Voltage | Support Customized | Support Customized |

Mini BST isn’t just compact; besides, with quick setup and easy operation, this electric motor cracker machine for sale helps you extract copper from end-of-life auto motors — improving your recovery rate while keeping costs low. It’s already a popular choice among scrap metal processors and automotive recyclers across multiple markets:

Cheap price and complete cutting &pulling functions, only small investment but high return to boost your profits.

Electric motor cracker machine adopting the pushing design, this design no need to change the baffle frequently when processing different diameter stators.

Recovers even challenging materials, effectively processes copper windings that are fully cut, burnt—maximizing yield from scrap.

A hands-free foot pedal controls the hydraulic system, making it ideal for operations that require frequent starts and stops.

After learning about the features of our small BST electric motor cracker, you might be wondering: what kind of materials can it actually process?

Below is a breakdown of the input materials it accepts and the final output you can expect:

Turn off the power supply of the machine in time when not in use, and thoroughly check whether there are any faults or wear on the parts. Perform regular maintenance and inspection of the equipment to prevent potential problems.

Clean the machine regularly, including the machine body, pulling device, gear, etc., to remove dust and debris and keep the equipment in good operating condition.

Wearing parts such as blades should be replaced in time to avoid affecting machine performance due to excessive wear.

Properly lubricate the rotating parts of the machine to reduce friction and wear and extend the service life of the machine.

Yes. The extraction method is designed to pull out the copper winding as complete as possible. This means less copper loss as fine fragments and a higher-quality whole copper windings you can sell for a better price.

Yes, we will test every machine before delivery and send you the working video. You also can come to us for inspection before delivery.

Don't worry, our machines are easy to install, just connect to the power. In addition, we will provide you with professional installation guidance, also any questions just contact us freely for solutions.

Of course. We provide clear documentation and technical support. Our goal is to ensure your recycling operation runs smoothly.

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :