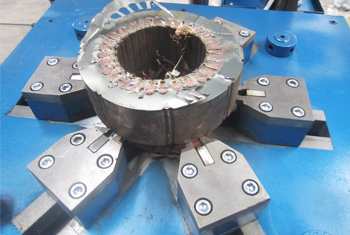

ST-400 Motor Stator Cutting And Pulling Machine is testing for Australian customer.

Our machine is tested for our client before shipping. With the shell cutting, stator cutting and copper winding pulling parts all in one, this machine can help our customers recycle motors highly efficiently and cost saving.

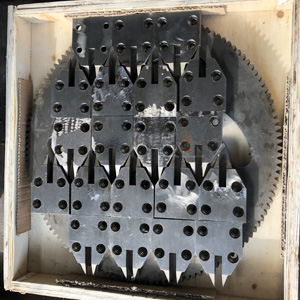

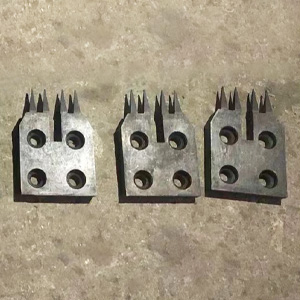

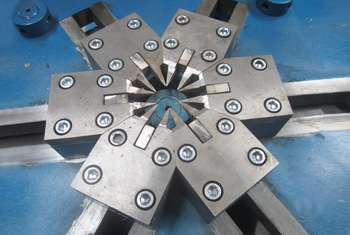

ST-400 motor stator extracting machine is designed for recycling copper from ordinary scrap motors. It consists of two main parts: the cutting part and the pulling part. The cutting part is a hydraulic system and contains two blades for cutting the motor shell and stator. The pulling part includes a fixture, jaws, and an ejector, which work together to extract copper windings from the motor stator.

| Model | ST-400 motor stator cutting and pulling machine | alternatives BSM-40 electric motor recyclers |

|---|---|---|

| Range | 90-250MM stator diameter | 50-500MM stator diameter |

| Weight | 1100KG | 670KG |

| Machine Size | L1800*W900*H1950MM | L1940*W1430*H1150MM |

| Power | 5.5KW | 7.5KW |

Our motor recycling machines come in various types, ST-400 belongs to one of the common electric motor recycling machines, for this kind of structure, is especially loved by European and USA customers. BSM-40 and BSM-50 are the golden partner, 2 machines working together have a bigger recycling range.

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :