Using the BSM-100 machine, you can get pure copper windings in just four simple steps below, greatly improving the recycling efficiency of the enterprise, helping the enterprise to occupy a favorable position in the market and increasing profits.

The BSM-100 used electric motor recycling machine can quickly recycle copper windings at one time. Compared with most motor recycling equipment on the market, our BSM-100 has a faster processing speed, it takes only 20 to 30 seconds to process a scrap motor stator. This unparalleled efficiency sets a new industry standard.

The BSM-100 electric motor recycling machine adopts our latest machine structure that has been tested in the market. The various parts of the machine are closely and reasonably connected to ensure that the machine can always maintain the best working performance. This means that enterprises do not need to spend much time inspecting the machine, pay extra for repairs, or frequently replace parts.

Our machine is designed for user-friendly operation, only one operator can complete the whole operation process without prior training. This can not only help the enterprise save a lot of training and labor costs but also ensure that recycling efficiency can be improved from the first day of using the machine.

Our machine is designed to maximize enterprises' profitability by efficiently recycling copper windings while ensuring their high quality. It can pull out the entire copper winding in one operation, with a recovery rate of almost 100%. The recovered copper windings, consisting of 100% pure copper, are free from impurities. This precision and accuracy can bring higher profits to enterprises.

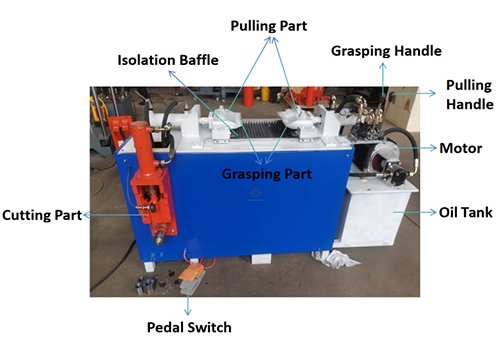

BSM-100 is on the basis of BSM-70 to add the cutting part. The components of BSM-100 used electric motor recycling machine mainly include a cutting part, isolation baffle, pulling part, grasping part, grasping handle, pulling handle, motor, oil tank, and pedal switch, as shown in the following figure:

Model | BSM-100 |

Weight | 320kg |

Size | L1800*W750*H1080MM |

Power | 3KW |

The BSM-100 electric motor recycling machine can process almost all kinds of small scrap electric motors with a diameter range of 60 to 200 mm, such as household appliances, washing machines, ac motors, industrial motor stators, electric toys, etc. You can use it in metal recycling center, motor manufacturer etc.

Turn off the power supply of the machine in time when not in use, and thoroughly check whether there are any faults or wear on the parts. Perform regular maintenance and inspection of the equipment to prevent potential problems.

Clean the machine regularly, including the machine body, pulling device, gear, etc., to remove dust and debris and keep the equipment in good operating condition.

Wearing parts such as blades should be replaced in time to avoid affecting machine performance due to excessive wear.

Properly lubricate the rotating parts of the machine to reduce friction and wear and extend the service life of the machine.

As an internationally renowned manufacturer of used electric motor recycling machines, our machines sell well all over the world and our customers are highly satisfied with our machines.

Please let us know your stators diameter and your capacity, we will recommend you the most suitable machine.

Yes, we will test every machine before delivery and send you the working video. You also can come to us for inspection before delivery.

Don't worry, our machines are easy to install, just connect to the power. In addition, we will provide you with instructions and professional installation technical guidance, If you have any questions during the installation process, you can contact us at any time and our technicians will provide you with technical support.

Electric motors have aluminum and copper components inside that have a high value. After recycling, you can sell it directly or use it as raw material for production, which can not only increase your economic benefits, but also reduce your production costs.

The most complete and best solutions for all your scrap motors recycling with advanced technology and higher efficiency.

Process Motor Shell | Process Motor Stator | Motor Shaft

Auto Starter Cutting | Auto Starter Pressing | Car Starter Heating | Car Starter Pulling Machine

Car Alternator Cutting Machine | Car Alternator Pulling Machine

Motor Stator Recycling Line | Motor Rotor Recycling Line | Whole Motor Recycling Plant

For Small Transformer Recycling

Compressor Shell Cutting Machine | Compressor Stator Recycling

Mainly for Recycling Ceiling Fan Motors

For All Kinds of Car Magnetic Switch

For All Kinds of Electric Bike Hub Motors

Mainly for Press All Kinds of Motor Parts | Support Customized

Please Fill Out The Following Form and Your Requests :